Our Products

Belt Tracking System

Conveyor Belts needs to run at the centre devoid of sway on both sides throughout the belt length for better productivity and longer life.

Belt sways result in off centre feeding in the feed zone causing heavy spillages involving Man power deployment, causing material wastages and environmental pollution.

Conventional self aligning carrying and return idlers with side guide rolls are found wanting to instantaneously center the belt, besides causing damages to the belt edge covers exposing the inner fabric to dust, thus reducing the belt life. Belt sways result in off centre feeding in the feed zone causing heavy spillages involving Man power deployment, causing material wastages and environmental.

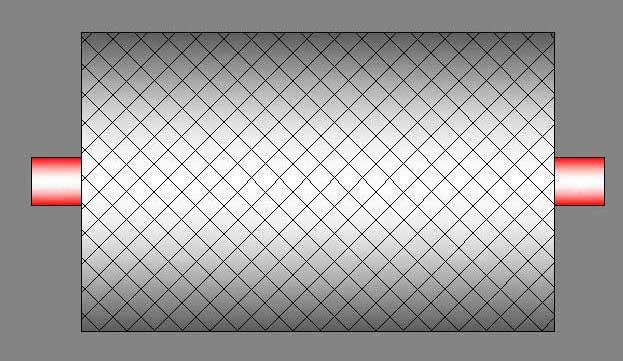

BMH Concare make Tracker Rollers are with instantaneous effective Belt sway tracking by working principle of differential rotational speeds concept, Rollers on return as well as carrying sides. Center pivoted Twin Tube construction design, Concentric rotation by two nos. lubricated double sealed bearings for full support, Instantaneous and Vibration free Tracking on lateral plane, Rubber lagging for effective tracking and longer life.

BMH Concare make Tracker Rollers are with instantaneous effective Belt sway tracking by working principle of differential rotational speeds concept, Rollers on return as well as carrying keeping conveyor belts at centre always.

Dust seal housing for fitment of bearings and Labyrinth seals on both sides for protection of dust entry.

- Best possible modular superior Design.

- Simple installation.

- Suitable for all belt speeds and capacity.

- Instantaneous & effective Belt sway tracking.

- Nil maintenance.

- Value for money.